Is DTF printing better than DTG?

DTG printing has long been the most popular method for T-shirt manufacturing and small batch production, but in the last two years, direct to film (DTF) has gained traction in the industry and is becoming more and more popular. To understand this change, we must first understand the contrast between these two printing methods.

Essentially, DTF is an inkjet transfer printing process: with DTF printing, you use an inkjet printer to print an image onto film. Immediately afterwards, you cover it with hot melt powder and then dry it. Once dry you can use a heat press to transfer the image.

DTG or direct to garment is sometimes referred to as digital garment printing. Essentially, DTG printing is a process of printing graphics onto textiles and clothing — most notably t-shirts for us. It uses modified inkjet technology to print whatever graphics you want onto the shirt. Our ink is completely safe and dries quickly. The ink will soak into your garment itself and become part of the shirt. This means the pattern has no chance to crack, peel or wash away over time.

DTF vs DTG printing

The abbreviations DTF and DTG are very similar, and both techniques use an inkjet printer with white ink. How are they different?

- Investment. Compared to the cost of a DTG press, DTF printing requires very little investment. A DTF kit costs almost one-tenth the price of a DTG printer.

- Print material. As mentioned, DTG can only be printed on cotton, but DTF can be printed on a variety of different fabrics.

- Use of white ink. DTF requires less white ink — about 40% white, while DTG printing requires 200% white. White ink tends to be the most expensive because it uses more and the pigment is titanium oxide, so reducing the amount of white ink used for printing can save a lot of money.

- Production time. DTF printing begins with printing designs on thin films. Then you have to add DTF powder on top. The printed film must then be cured and the design transferred from the film to the fabric. With DTG printing, the printer prints directly on the garment and the production time is greatly reduced compared to DTF printing.

- Printing touch and finish. DTF has a slightly “plastic” surface, very similar to screen transfer printing. However, the ink is very elastic, which prevents the print from cracking when the garment is stretched. With DTG printing, the ink is fully absorbed into the garment, resulting in a finer effect and better integration with the fabric.

- White strength and purity: In this case, DTG printing produces a purer, more intense white. In the case of DTF, white is less pure and intense.

- Consumable costs: Both technologies have low production costs. Although it appears that DTF uses more consumables in the printing process, the final cost of a T-shirt printed with this technique is slightly lower than a T-shirt printed with DTG.

DTG or DTF which is better?

In the next decade, experts expect the DTF (direct film production) industry to grow massively. Demand for fabrics has consistently outstripped supply, and it has become increasingly common to find textiles in a variety of patterns and colors among everyday items. Compared to other printing techniques, DTF transfer printing is generally more cost-effective because there is no restriction on the type of fabric. It makes the overall cost of the items sold much lower, thus increasing the profit margins of many businesses.

Although DTF printing appears to have advantages over DTG printing, the two technologies have quite different applications and functions. If you need high color output but don’t want to spend too much money, DTF may be a better choice for small-scale printing. However, DTG now offer more adaptable printing equipment that enables faster, more flexible printing.

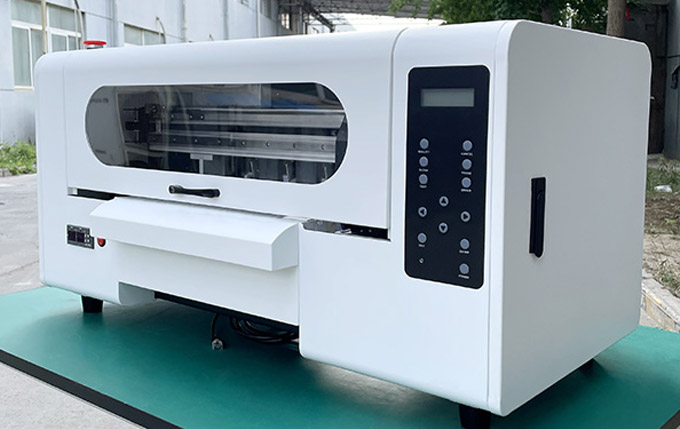

Looking for the best DTF printer?

Want to start t shirt printing business? Textek is the Largest and Most Reliable DTF Printer Manufacturer in China! DTF printer can for any color, any fabric t shirts, easy operation, make your business improved. Textek has A3 30cm DTF printer and large size 60cm DTF printer, low cost, big profit.