What is required for DTF Printing?

The prerequisites for DTF printing do not require users to spend a lot of money. Whether you are currently engaged in one of the above digital textile printing processes, wish to expand into DTF printing as an extension of your business, or start using DTF, you must invest in the following.

PET film

PET film is used in DTF printing process. These films are different from those used in screen printing, which are characterized by a thickness of 0.75 mm and superior transfer performance. These films are often marketed as DTF transfer films. DTF films are available in cut sheets (for small scale use) and reels (for commercial setups). The classification of another PET film depends on the type of peeling after transfer. Films are classified as hot or cold stripped based on their temperature.

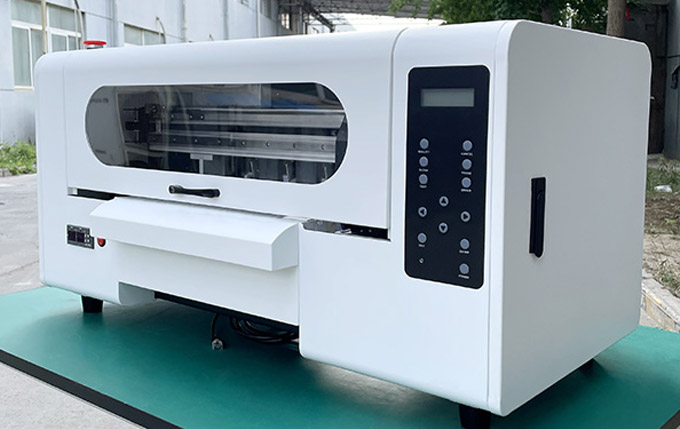

Want to start t shirt printing business? Textek DTF printer is the best choice for you. DTF printer can for any color, any fabric t shirts, easy operation, make your business improved.

Operating system

Software is a key component of the process. Software has a great impact on printing quality, ink color properties and the final printing properties of the fabric after transfer. DTF transfer must use professional RIP software that can handle CMYK and white color. Direct film printing programs can control the color curve, the amount of ink, the size of ink drops, and other aspects that help achieve the desired printing effect.

DTF printing powder

DTF printing powder is white and acts as an adhesive to bind the colored pigments from the print to the fibers of the cloth. DTF hot melt powder has a variety of micron grade products. A suitable quality shall be selected according to the requirements.

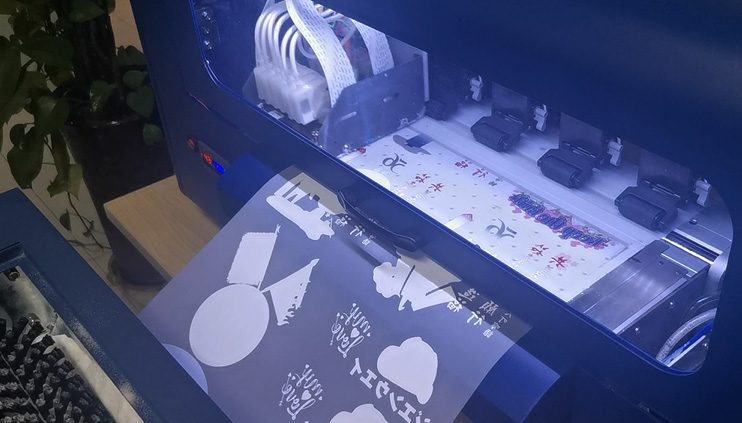

DTF printing ink

These pigment inks are available in cyan, magenta, yellow, black and white tones and have been developed specifically for DTF printers. White ink is a unique ingredient that creates a white background on which it will be printed before the coloured pattern is printed on the film.

Shake powder machine

Commercial DTF systems use a self-shaking powder machine to evenly distribute the powder and eliminate any remaining powder.

Curing equipment

Curing furnace is a compact industrial heating device for melting hot melt powder of transfer film. This can also be done with a hot press; However, this must be done in a non-contact manner. Use a hot press to transfer the picture printed on the film to the cloth. It can also be used to melt the hot melt powder of DTF film.